Motor-to-Gearbox Shaft Adapter

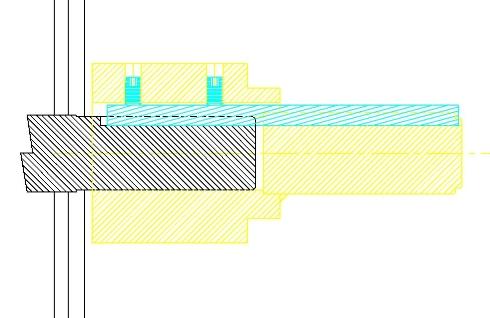

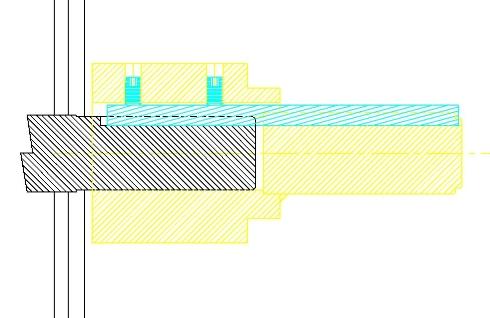

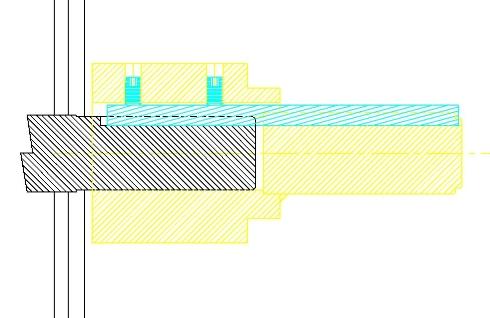

Here is the shaft-adapter in cross-section:

Motor-to-gearbox shaft adapter

I needed a lathe to do the finishing work on the shaft adapter. I was

contemplating this problem when I noticed a big lathe sitting nearby, along

with a motor and VFD. With a 2x12, wooden wedges, some carriage bolts and a

taper-lock sleeve for a pulley in my junk box, I had the EE running with the

new motor mounted outside the lathe:

Temporary direct spindle drive

Below are some pictures during fabrication. The female part is bored with a

step so the male part slips into it and has the keyway broached. The male part

is slotted. The two parts are welded together and all the finish turning and

boring is referenced to the TGP surface of the male part.

Slotting a piece of TGP shaft

Shaft adapter after welding

Final boring of shaft adapter

Here are two views of the the finished part. The key is rectangular and is

held captive by the set-screws in the female part. Note the polished shoulder

for an oil seal and the step at the end of the male shaft for checking alignment

with the gearbox output gear bore.

The bore was a tight fit on the motor shaft, but I still ended up putting two

more pairs of set-screws at 120 and 240 degrees from the key to get rid of

0.002" of runout caused by the original two set-screws deflecting the shaft

away from center. With these installed and tweaked, there was negligible

runout on the male shaft.

Here is how I aligned the adapter on the motor shaft:

Next Page

Back to Main Page